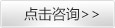

飼料混合機生產加工過程控制與最終的飼料品質、生產安全、加工效能和工藝的穩定性密切相關,所以深入了解,實現對飼料生產過程的有效把握和控制對飼料品質和生產效益有著舉足輕重的作用。

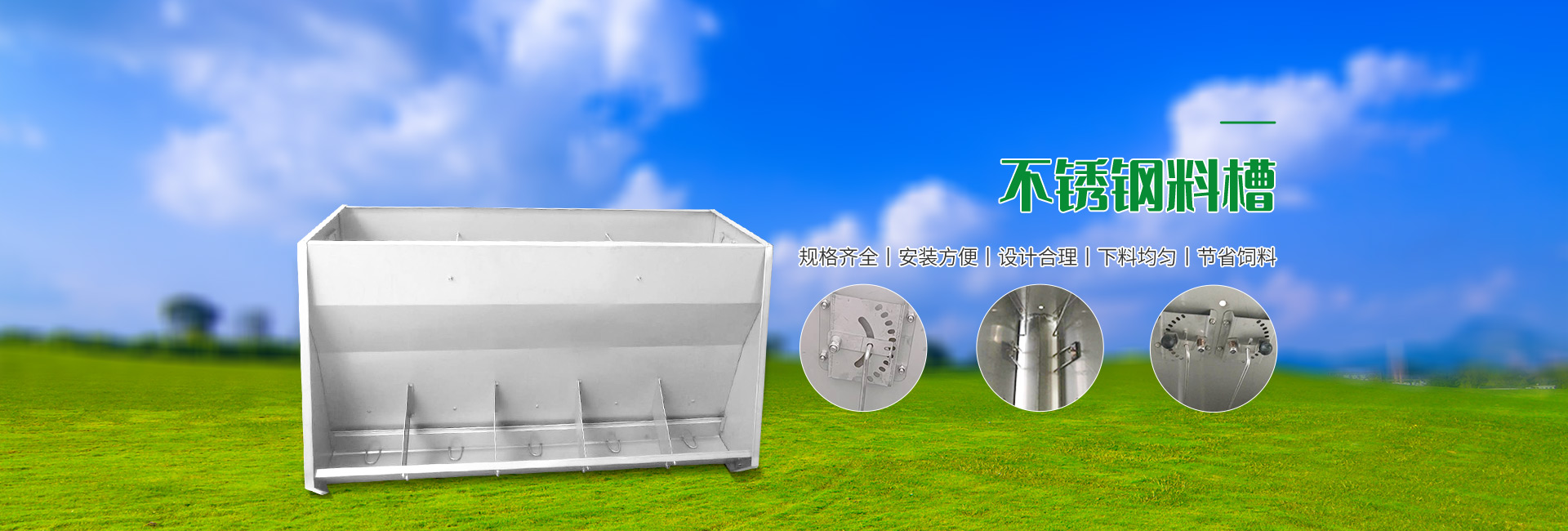

1、飼料混合機生產加工過程需要正確認識飼料顆粒質量檢測包括顆粒的外觀、長度、顏色、光滑度以及水分含量等多種多種屬性,其檢測方法也多是以人工檢測,繼而調整控制的。

Mixer need a correct understanding of the production process quality inspection feed particles including particulate appearance, length, color, smoothness and moisture content, and other variety of attributes, which are mostly based on

manual detection methods to detect, and then adjust the controls.

2、飼料混合機生產車間的安全包括人身安全、財產安全以及生產安全,這也是整個生產流程中最重要的環節控制。對于人身、財產安全性是對整個生產車間的基本要求,也是持續健康生產的保證,而生產設備的安全則影響著整個飼料生產進度。

Mixer workshop safety, including personal safety, property, security and safety, which is the entire production process is the most important aspect of control. For personal and property safety is a basic requirement of the entire workshop, as well as to ensure the continued health of the production, and safety equipment are affecting the entire feed production schedule.

3、飼料混合機http://www.862010.cn/效能的把握決定著飼料生產廠家的效益問題,所以,這也是生產控制的重要依據。在飼料生產中,若飼料設備的主電機工作電流低于額定電流,不會對生產設備造成明顯影響,卻會消耗很多的人力和電力。

Grasp feed mixer performance determines the effectiveness of the feed manufacturer, so this is an important basis for production control. In feed production, if the main motor operating current feed device is less than the rated current, will not cause significant impact on production equipment, but it will consume a lot of manpower and electricity.

4、飼料混合機http://www.862010.cn/生產工藝的穩定性主要體現在飼料粉碎、混合、制粒和冷卻等單機設備工作的穩定上。如不能合理控制,某些設備可能會出現周期性的變動,影響最終的產品規格和生產效能。

Mixer stability of the production process is mainly reflected in the steady feed grinding, mixing, pelleting and cooling equipment and other stand-alone work. If you can not reasonably control, some devices may appear cyclical changes

affect the final product specifications and production efficiency.